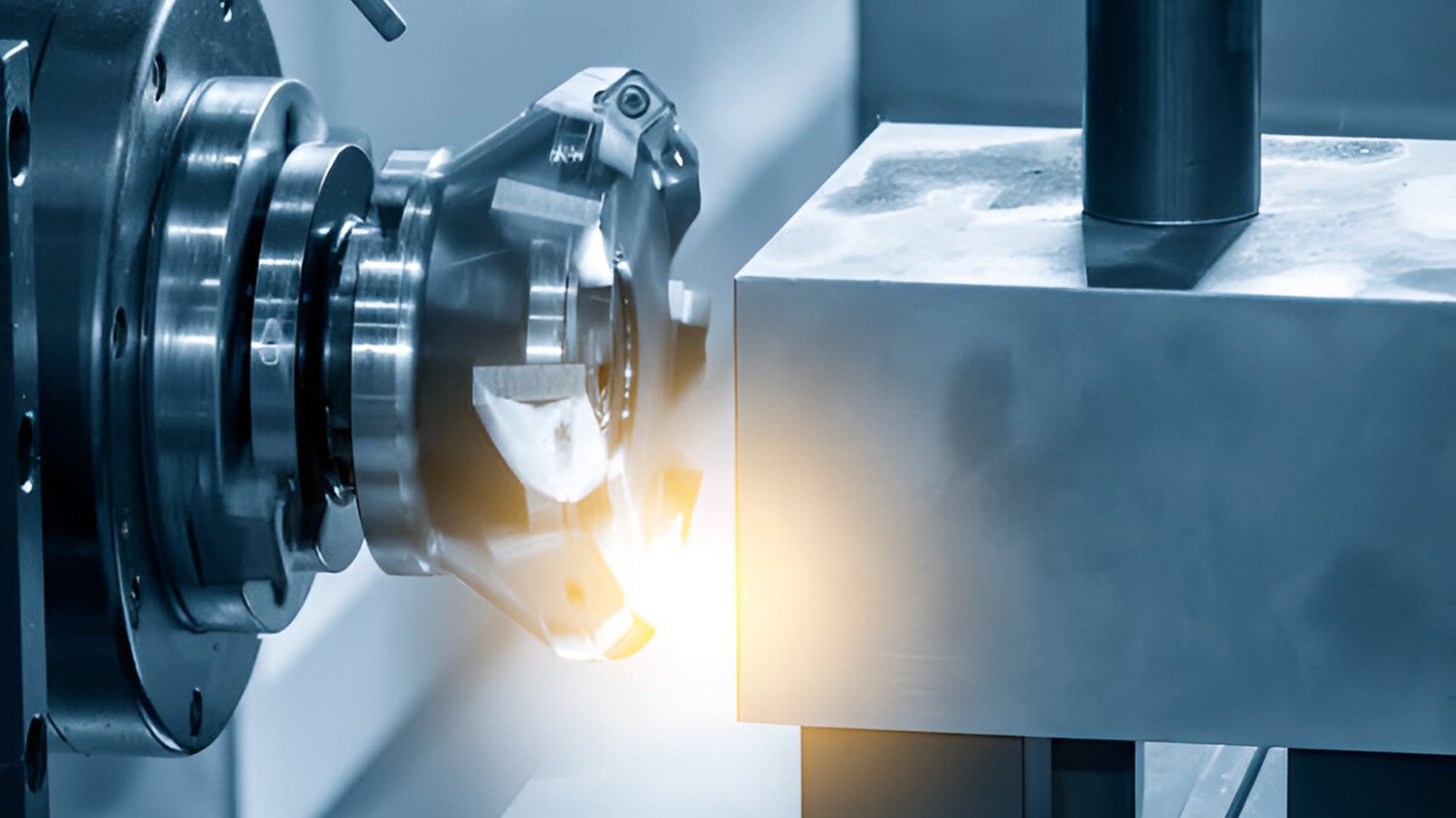

The world of CNC machining: A comprehensive guide

You might have heard of the term CNC before. The term stands for Computer Numerical Control. CNC Machining is a manufacturing process that encompasses a range of computer-controlled machines. Such machines use pre-programmed software to control the movement of manufacturing tools and machinery. Therefore, CNC machining is all about precision and accuracy, resulting in refined output in different manufacturing applications.

The Benefits of CNC Machining:

CNC machining offers a host of benefits, making it an excellent solution for various manufacturing applications:

1. Precision:

CNC machines make use of automated computer software, which ensures high levels of accuracy and precision. This aspect is a big advantage, particularly in situations where you need to produce in bulk. CNC machines can replicate the same operation with the utmost precision, leading to flawless outputs every time.

2. Increased efficiency:

CNC machining helps enhance efficiency levels by streamlining the manufacturing process. CNC machines can work round the clock without stopping, leading to a faster turnaround time on orders.

3. Reduced waste:

CNC machining can be wasteful at times if not correctly executed. However, CNC machines leave little room for errors, ensuring there are no wasted materials. This aspect helps save on costs and reduces material wastage.

4. Versatility:

CNC machines are versatile and can handle various manufacturing processes, including turning, milling, routing, drilling, and lathing. This versatility makes CNC machining an ideal solution for various industries, including aerospace, automotive, medical, and electronics.

Types of CNC Machines:

The world of CNC Machining is vast and encompasses an array of machines. Below are some of the most common CNC machines in use today:

1. CNC Mills:

A CNC mill is a computer-controlled machine tool. It mills (or drills) materials using a cutting tool held in a rotating spindle. These machines help produce large quantities of complex metal, plastic, or wood components, with high precision and accuracy.

2. CNC Lathes:

A CNC lathe is a computer-controlled machine tool that performs cylindrical operations. This machine can work wood, plastic, and metals to produce a range of end products, including shafts, hubcaps, and automotive components.

3. CNC Plasma Cutters:

CNC plasma cutters are computer-controlled machines that make use of plasma torches to cut various materials. These machines help achieve high-quality cutting finishes on various materials, including mild steel, aluminum, and stainless steel.

4. CNC Routers:

A CNC router is a computer-controlled machine that is used to manufacture flat or low-profile materials. These machines are used to produce wood items such as engraved furniture, signs, or carvings.

What materials can CNC machines mill?

CNC machines can mill a broad spectrum of materials, including:

1. Metals:

CNC machines can work with a range of metals, including aluminum, brass, black steel, copper, and titanium, to name a few. The machines make use of drills and cutting tools fitted in spindles to mill the materials into the desired shape.

2. Woods:

CNC machines can work with woods such as plywood, hardwood, and MDF to create a range of products, including furniture, fixtures, and flooring.

3. Plastics:

CNC machines can work with different plastics, including polycarbonate, acrylic, nylon, and PVC. These machines can mill the plastics into various shapes and lend precision to aid the manufacturing of complex components.

4. Composites:

CNC machines can work on composites by combining various materials to achieve the desired results. For example, CNC machines can work on carbon fiber composites used in building aerospace and automotive components.

How is CNC Machining Done?

CNC machining follows a simple process that comprises the following steps:

1. Design and Programming

A designer or engineer creates a computer design or model of the component to be produced. The design is translated into a software program that the CNC machine understands, determining its exact specifications.

2. Material Setup

The chosen material is loaded onto the CNC machine's work table, ready for machining.

3. Machine Preparation

The prepared software program is downloaded into the machine's controller and acts as a guideline for the machine. The machine operator sets the machine's operational parameters, including machine speeds and cutting depths before starting the machining process.

4. Cutting Operations

The machine operator initiates the CNC machine's cutting operations, and the machine's cutter devices begin to mill or drill the selected material, guided by the software program. The machine operates until the final end product is achieved.

CNC Machining: The Future

CNC machining rests at the forefront of manufacturing technology, paving the way for new possibilities and opportunities in the future. With the advancements made in computer technologies, there is no limit to what can be produced using CNC machines. As 3D printing technology improves, CNC machining will continue to grow as 3D printed prototypes lead to efficient mass production. In conclusion, CNC machining is a technology that promises to revolutionize the manufacturing industry.