Custom Cnc Machining Parts: A Comprehensive Guide

Introduction

In the world of manufacturing and engineering, the demand for precision and customization is ever-growing. Custom CNC machining parts have become an essential solution for industries seeking high-quality components that meet their specific requirements. This article aims to provide a comprehensive guide on custom CNC machining parts, exploring their benefits, applications, and key considerations.

1. Understanding Custom CNC Machining Parts

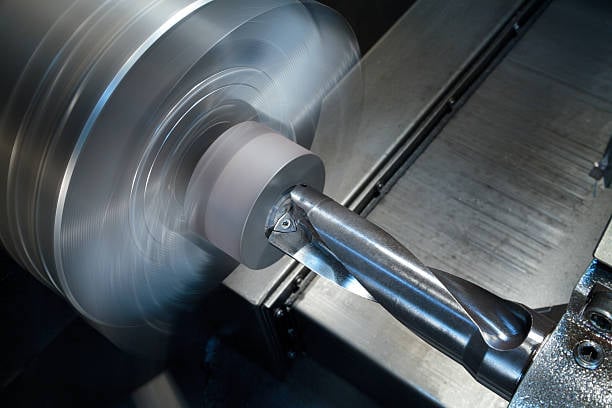

Custom CNC machining parts are components manufactured using computer numerical control (CNC) machines. These machines utilize computer-aided design (CAD) software to precisely control the movements of cutting tools and create complex shapes and designs with high accuracy. The ability to customize these parts according to specific designs and requirements makes them highly sought after in various industries.

2. Benefits of Custom CNC Machining Parts

When it comes to manufacturing, custom CNC machining parts offer several advantages:

a) Precision: CNC machines can achieve extremely high levels of precision, allowing for intricate designs and tight tolerances. This precision ensures that the final product meets the required specifications.

b) Flexibility: Custom CNC machining parts can be produced in a wide range of materials, including metals, plastics, and composites. This flexibility enables manufacturers to choose the most suitable material for their specific applications.

c) Cost-Effective: While the initial setup cost for CNC machines can be significant, the long-term benefits outweigh it. Custom CNC machining parts require minimal manual labor, reducing labor costs and increasing production efficiency.

d) Faster Turnaround Time: CNC machines automate the manufacturing process, resulting in faster production cycles. This quick turnaround time allows businesses to meet tight deadlines and respond swiftly to market demands.

3. Applications of Custom CNC Machining Parts

Custom CNC machining parts find applications in various industries, including:

a) Aerospace: The aerospace industry relies heavily on custom CNC machining parts for manufacturing critical components such as turbine blades, engine parts, and structural elements.

b) Automotive: Custom CNC machining parts are widely used in the automotive industry for producing engine components, transmission parts, and customized accessories.

c) Medical: In the medical field, custom CNC machining parts play a vital role in manufacturing surgical instruments, prosthetics, and medical device components with exceptional precision.

d) Electronics: Electronics manufacturers utilize custom CNC machining parts to create intricate circuit boards, heat sinks, and other components that require high precision and reliability.

4. Factors to Consider for Custom CNC Machining Parts

When opting for custom CNC machining parts, it is essential to consider the following factors:

a) Material Selection: Different materials possess varying properties, such as strength, durability, and conductivity. Choosing the right material is crucial to ensure the desired performance and functionality of the final product.

b) Design Complexity: CNC machines can handle complex designs, but certain features may require additional machining processes or incur higher costs. It is important to optimize the design for manufacturability to minimize complications.

c) Tolerances: Specify the required tolerances for the part, as tight tolerances may require additional machining steps or specialized equipment.

d) Surface Finish: Determine the desired surface finish for the part, as different machining techniques and tools can achieve varying levels of smoothness and texture.

5. Custom CNC Machining Parts vs. Standard Parts

Custom CNC machining parts offer several advantages over standard parts:

a) Tailored Design: Custom CNC machining parts can be designed to perfectly fit the specific requirements of a project, eliminating the need for modifications or adaptations.

b) Higher Quality: With CNC machines, manufacturers can achieve higher precision and accuracy compared to standard machining methods, resulting in superior quality parts.

c) Improved Performance: Custom CNC machining parts can be optimized for better performance, considering factors such as weight reduction, increased strength, and improved functionality.

d) Enhanced Efficiency: Custom CNC machining parts eliminate the need for additional assembly or modifications, reducing production time and increasing overall efficiency.

6. Finding a Reliable Custom CNC Machining Parts Supplier

Choosing a reliable supplier for custom CNC machining parts is crucial to ensure the quality and timely delivery of your components. Consider the following when selecting a supplier:

a) Experience and Expertise: Look for a supplier with extensive experience in CNC machining and a proven track record in delivering high-quality parts.

b) Quality Assurance: Inquire about the supplier's quality control processes and certifications to ensure they meet industry standards and regulations.

c) Capabilities: Assess the supplier's capabilities in terms of equipment, materials, and capacity to handle your specific project requirements.

d) Communication and Support: Effective communication and responsive customer support are essential for a smooth collaboration and timely delivery of your custom CNC machining parts.

7. Future Trends in Custom CNC Machining Parts

The custom CNC machining parts industry is continually evolving to meet the growing demands of various sectors. Some future trends to watch out for include:

a) Additive Manufacturing: The integration of additive manufacturing techniques, such as 3D printing, with CNC machining processes opens up new possibilities for complex part designs and rapid prototyping.

b) Automation and Robotics: The use of advanced robotics in CNC machining processes can further enhance efficiency, precision, and productivity while reducing manual labor.

c) Artificial Intelligence (AI) Integration: AI algorithms can optimize CNC machining operations, minimize errors, and improve overall process efficiency.

d) Sustainable Manufacturing: Custom CNC machining parts can be produced using eco-friendly materials and processes, contributing to a more sustainable manufacturing industry.

8. Conclusion

Custom CNC machining parts are revolutionizing the manufacturing industry by offering precise, customizable components for various applications. Their benefits, applications, and key considerations make them an attractive choice for industries seeking high-quality, tailored solutions. As technology continues to advance, the future of custom CNC machining parts holds even more exciting possibilities.