What is Electro Erosion Wire Cutting?

Electro erosion wire cutting, also known as wire EDM (Electrical Discharge Machining), is a cutting-edge technology used in various industries for precision machining. This non-traditional machining process involves the use of a thin, electrically charged wire to cut through conductive materials with exceptional accuracy and precision. It is widely regarded as one of the most efficient methods for creating complex shapes and intricate designs.

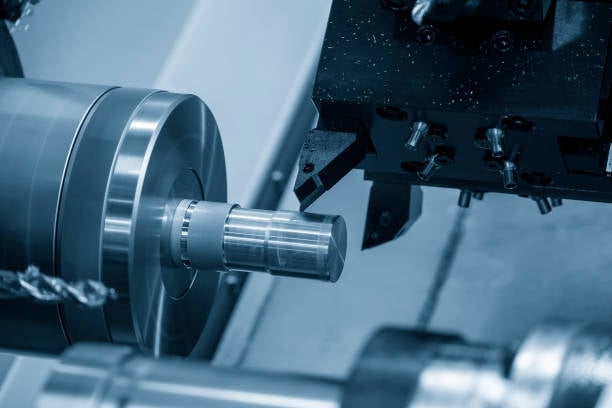

The Working Principle of Electro Erosion Wire Cutting

To understand how electro erosion wire cutting works, it is essential to comprehend its underlying principle. This process utilizes electrical discharges to remove material from the workpiece. A thin wire, typically made of brass or copper, is fed through the material while an electric current passes through it. As the wire approaches the workpiece, the electric current creates a series of controlled sparks or electrical discharges that erode the material, thereby cutting it with extreme precision.

The Advantages of Electro Erosion Wire Cutting

Electro erosion wire cutting offers numerous advantages over conventional cutting methods. Some of the key benefits include:

- Precision: This method enables the creation of intricate and complex shapes with high precision, ensuring minimal material wastage and superior finished products.

- Versatility: It can be used to cut a wide range of conductive materials, including hardened steel, titanium, copper, and more.

- No Contact: As the wire does not physically touch the workpiece, there is no risk of tool wear or damage to the material, resulting in a longer tool life.

- Minimal Heat Affected Zone: Electro erosion wire cutting produces minimal heat, reducing the chances of thermal distortion in the material being cut.

- Complex Geometries: This technology allows for the creation of intricate and complex 3D shapes that may be challenging to achieve with traditional machining methods.

Applications of Electro Erosion Wire Cutting

Electro erosion wire cutting finds applications in various industries due to its exceptional precision and versatility. Some of the common applications include:

- Tool and Die Making: Electro erosion wire cutting is widely used in the production of molds, dies, and tooling components for industries such as automotive, aerospace, and electronics.

- Medical Device Manufacturing: The medical industry relies on this technology to create intricate surgical instruments, implants, and other medical devices.

- Prototyping and Rapid Manufacturing: The ability to create complex shapes quickly and accurately makes electro erosion wire cutting ideal for prototyping and rapid manufacturing processes.

- Electronics and Microtechnology: This technology is used in the production of microelectronic components, circuit boards, and other intricate electronic parts.

- Aerospace and Defense: Electro erosion wire cutting is employed in the manufacturing of turbine blades, engine components, and other critical parts used in the aerospace and defense industries.

Choosing the Right Electro Erosion Wire Cutting Machine

When considering electro erosion wire cutting for your machining needs, selecting the right machine is crucial. Here are some factors to consider:

- Machine Accuracy: Look for machines that offer high precision and repeatability to ensure the desired quality of your finished products.

- Workpiece Size: Consider the maximum workpiece size that the machine can accommodate, as it should align with your specific project requirements.

- Wire Diameter: Different machines support various wire diameter ranges, so choose one that suits your needs.

- Control System: Ensure the machine has an intuitive control system that allows for easy programming and operation.

- Additional Features: Look for features like automatic wire threading, advanced filtration systems, and adaptive control for enhanced efficiency and productivity.

Maintaining Electro Erosion Wire Cutting Machines

Proper maintenance is essential to ensure the longevity and optimal performance of electro erosion wire cutting machines. Here are some maintenance tips:

- Regular Cleaning: Clean the machine regularly to remove debris, swarf, and other contaminants that can affect its performance.

- Wire Inspection: Regularly inspect the wire for signs of wear or damage. Replace worn wires promptly to maintain accuracy.

- Fluid Management: Properly manage dielectric fluid levels and replace it as needed to ensure efficient cutting and prevent contamination.

- Follow Manufacturer Guidelines: Adhere to the manufacturer's recommended maintenance schedule and follow their guidelines for optimal machine performance.

The Future of Electro Erosion Wire Cutting

As technology continues to advance, so does the potential for electro erosion wire cutting. Researchers and manufacturers are constantly exploring ways to improve this machining process, including:

- Increased Cutting Speeds: Efforts are being made to enhance the cutting speeds of wire EDM machines without compromising on precision.

- Improved Surface Finish: Researchers are working on developing techniques to achieve even smoother surface finishes on the machined components.

- Advanced Automation: Automation features, such as robotic wire threading and adaptive control systems, are being integrated into wire EDM machines for increased productivity.

- Enhanced Wire Materials: New wire materials with improved conductivity and wear resistance are being developed to enhance the cutting capabilities of wire EDM machines.