Introduction

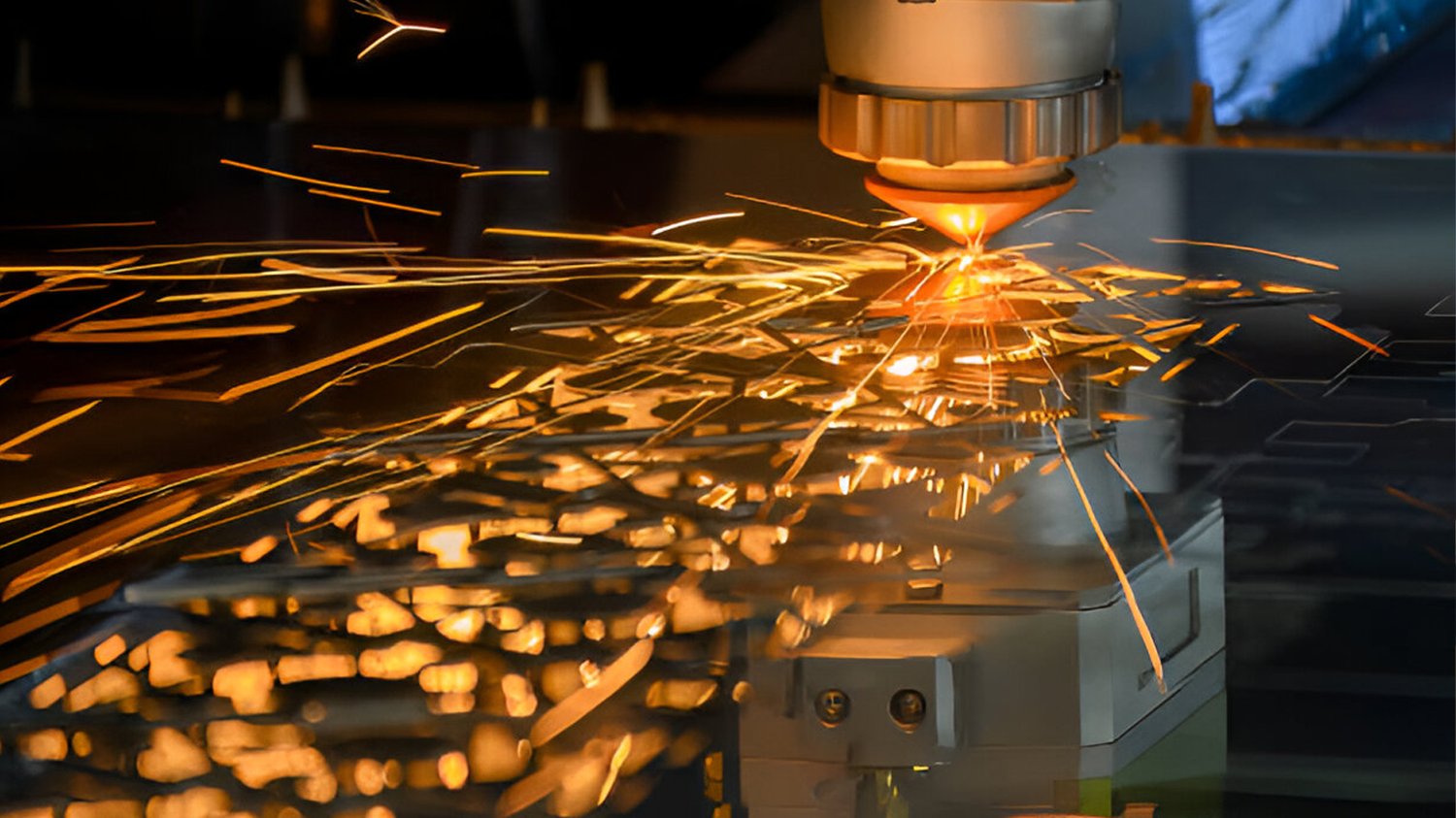

Heat treatment machining is a vital process used in the manufacturing industry to improve the durability, toughness, and hardness of metallic materials. In this article, we will explore the benefits and applications of heat treatment machining to enhance the mechanical and chemical properties of metals.

The Fundamentals of Heat Treatment Machining

Heat treatment machining involves subjecting metallic materials to different temperatures and cooling rates to alter their microstructure. The process usually entails the use of heating equipment like furnaces and ovens to achieve specific temperature ranges and cooling methods like quenching, annealing, and tempering to attain the desired material properties.

The Advantages of Heat Treatment Machining

Heat treatment machining offers numerous benefits that make it a preferred technique in the manufacturing industry. Some of these benefits include:

- Enhanced durability and toughness of metallic materials.

- Improved hardness and wear resistance, making materials suitable for harsh industrial environments.

- Increased strength and resistance to mechanical stresses

- Improved corrosion resistance, thereby increasing the life span of materials.

- Refining microstructures to remove defects like porosity and nonmetallic inclusions.

Affordability and Accessibility of Heat Treatment Machining

Heat treatment machining is an affordable and accessible process due to the availability of modern heat treatment technologies and specialized service providers. Most manufacturing companies can access heat treatment service providers, thereby increasing the quality and performance of the products they manufacture. Furthermore, different heat treatment techniques like gas nitriding, carburizing, and induction heating are available, providing versatility in the choice of technique to suit specific material properties.

Applications of Heat Treatment Machining

Heat treatment machining has various applications in various industries, some of which include:

- Manufacturing of automotive parts like gears, axles, and engine components

- Production of aerospace materials like turbine blades, nozzle guide vanes, and landing gear systems

- Manufacture of tools like saws, drill bits, and cutting blades

- Production of industrial and construction materials like metals for bridges, rail lines, and pipelines

The Importance of Heat Treatment Quality Control

Quality control is a crucial aspect of heat treatment machining. The use of modern equipment, validated processes, and robust quality systems ensures the accuracy, repeatability, and traceability of the heat treatment process. Quality control measures like non-destructive testing, in-process monitoring, and post-treatment testing help identify defects and ensure compliance with industry standards.

The Challenges of Heat Treatment Machining

Despite its numerous benefits, heat treatment machining is not without its challenges. Some of these challenges include:

- Difficulty in achieving uniform heating and cooling of materials

- Potential deformation or warping of materials due to thermal stresses

- Difficulty in predicting the behavior of the material after heat treatment

- Potential cracking or failure of the material due to uneven cooling rates.

The Future of Heat Treatment Machining

The future of heat treatment machining lies in the adoption of advanced technologies like digital control systems, artificial intelligence, and automation. Such technologies will enhance the accuracy, repeatability, and efficiency of the heat treatment process, lowering associated costs and increasing product quality. Additionally, there will be more research towards developing new heat treatment techniques and improving existing ones for better performance and reduced environmental impact.

The Environmental Impact of Heat Treatment Machining

Heat treatment machining has varying environmental impacts depending on the technique used. Some environmental impacts associated with heat treatment machining include:

- Release of greenhouse gases and toxic emissions from heat treatment furnaces

- Release of wastewater and hazardous chemicals during the cleaning process

- Increased energy consumption during the heat treatment process leading to higher carbon footprints

Conclusion

Heat treatment machining is a vital process used in the manufacturing industry to improve the mechanical and chemical properties of metallic materials. The process offers numerous benefits, and its affordability and accessibility make it a preferred technique for various applications. Despite its challenges and environmental impact, heat treatment machining has a promising future due to the adoption of advanced technologies and continued research to improve existing techniques.