Introduction

Mold CNC Machining is a process of producing precision parts, molds, and dies using a computer-controlled machine tool. This process has revolutionized the manufacturing industry, allowing companies to produce high-quality and complex designs with accuracy and speed. In this guide, we will explore the various aspects of Mold CNC Machining and its applications.

Mold CNC Machining Process

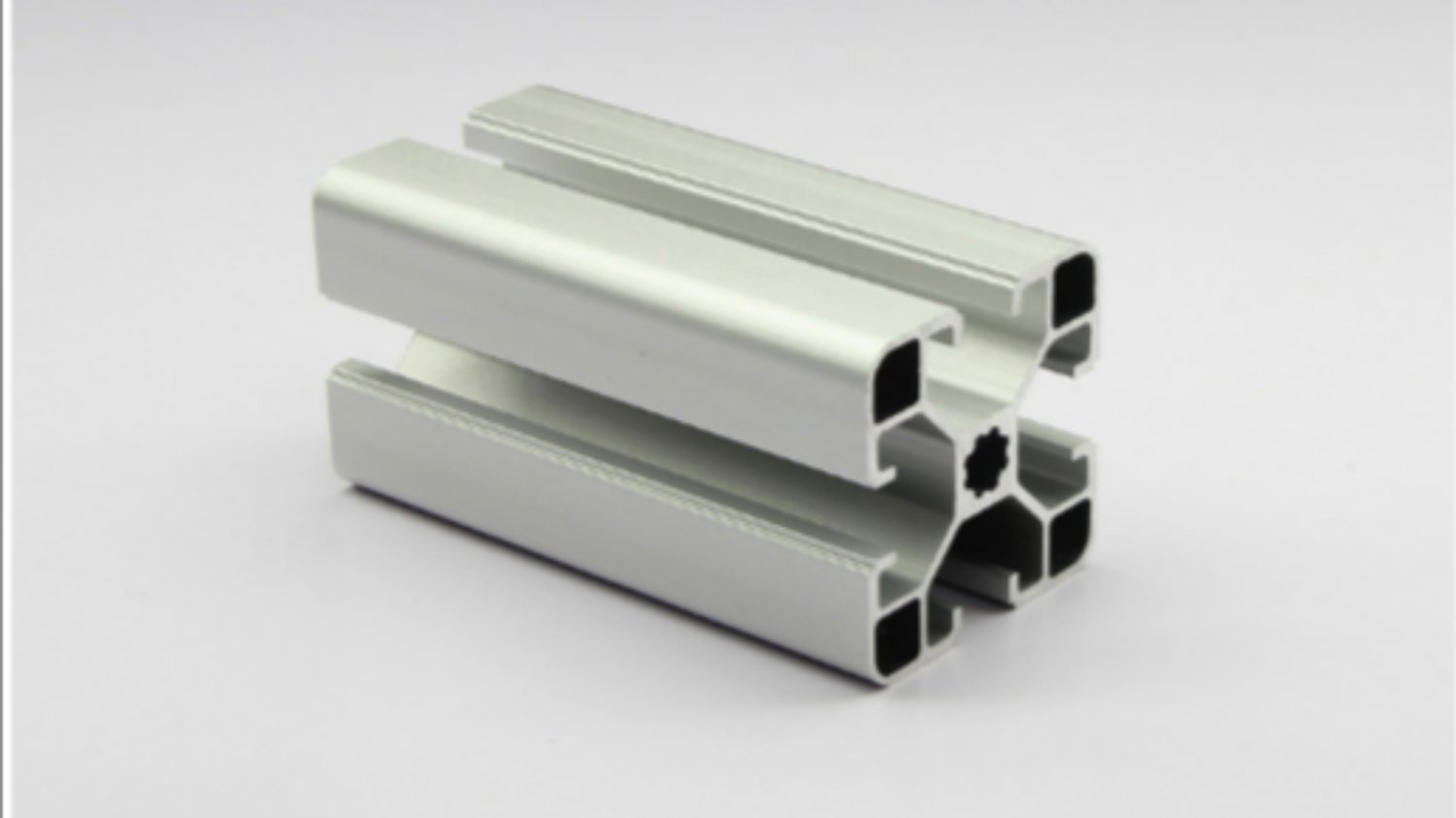

The Mold CNC Machining process involves the use of a computer-controlled machine tool to remove material from a workpiece. The machine tool creates a part by cutting away from solid material. The process can be automated, reducing the chances of human error and allow for consistent production. The process can be executed in a variety of materials, including plastics, metals, and composites.

Applications of Mold CNC Machining

Mold CNC machining is an essential tool for a wide range of applications. It can be used to produce high-quality products, from automotive parts to aerospace components. The technology has also been extensively used in creating molds for consumer goods such as toys, household goods, and medical devices. The ability to produce high-quality molds has minimized mold-making time and improved quality. Mold CNC machining is also vital in the creation of intricate parts and dies, where accuracy is of utmost importance.

The benefits of Mold CNC Machining

Mold CNC Machining has numerous advantages, including:

- High precision and accuracy

- Reduced lead time in manufacturing

- Can produce complex parts with high dimensional accuracy

- A wide range of materials can be machined, including metals, plastics, and composites

- Elimination of human error, leading to consistent production

Mold CNC Machining Tools and Equipment

The CNC machine tool is the primary equipment used in the Mold CNC Machining process. It is a computer-controlled machine that performs various machining operations to produce a part. The machines can be divided into several types, including horizontal and vertical machining centers and multi-axis machines. The CNC machines are supported by specific software that controls and manages the machining process. These tools and equipment help to ensure that high precision and accuracy are attained during the Mold CNC machining process.

Choosing a Mold CNC Machining Service Provider

The choice of a Mold CNC Machining service provider is crucial in ensuring high-quality production. Some factors to consider when selecting a service provider include:

- Experience and expertise in the Mold CNC Machining field

- The capability to fabricate complex designs and shapes

- The ability to handle various materials, including metals, plastics, and composites

- The availability of advanced tools and equipment

- Sufficient quality control measures to ensure high standards

Mold CNC Machining Quality Control Measures

Quality control is essential in ensuring that the final product meets high standards. Some of the quality control measures used in Mold CNC Machining include:

- Regular calibration of machines and tools to maintain accuracy

- Periodic quality inspections to eliminate defects

- The use of advanced software to monitor the process and prevent errors

- The use of specialized software to generate G-code from CAD models and inspect designs before the manufacturing process begins.

- The use of multiple-axis machines, which can ensure that parts are machined in the correct sequence, reducing error and saving time.

The Future of Mold CNC Machining

The future of Mold CNC Machining is bright. Advancements in software technology and machine tools are making the process more effective, faster, and flexible. The industry is predicted to grow significantly in the coming years, with increasing demand from various industries such as healthcare, aerospace, automotive, and others.

Conclusion

Mold CNC Machining is a technology that is revolutionizing the manufacturing industry. It has numerous advantages, including increased accuracy, reduced lead time, and great flexibility. A wide range of industries has embraced the technology, and with the predicted growth in the coming years, it is an exciting time for production technology. Whether you are a small or large scale manufacturer, embracing Mold CNC Machining might be the key to unlocking your full production potential.