Introduction

Mold Component Manufacturing is a complex business that involves creating molds and components used to produce a wide variety of consumer goods. The process requires a high degree of precision and attention to detail to ensure that the final product is both functional and aesthetically pleasing. In this article, we will explore 10 different aspects of mold component manufacturing, including its history, materials, processes, and applications.

History of Mold Component Manufacturing

Mold component manufacturing has been around for centuries, with the earliest examples of molded objects dating back to the ancient Egyptians. The process became more popular during the industrial revolution, when the demand for mass-produced consumer products increased. Today, mold component manufacturing is a multi-billion dollar industry that plays a critical role in the production of everything from plastic toys to medical devices.

Materials Used in Mold Component Manufacturing

The materials used in mold component manufacturing vary depending on the type of product being produced. Common materials include plastics, metals, and composites. Each material has its own unique properties that make it well-suited for certain applications. For example, plastic is often used in the production of consumer goods because it is lightweight, affordable, and easy to mold.

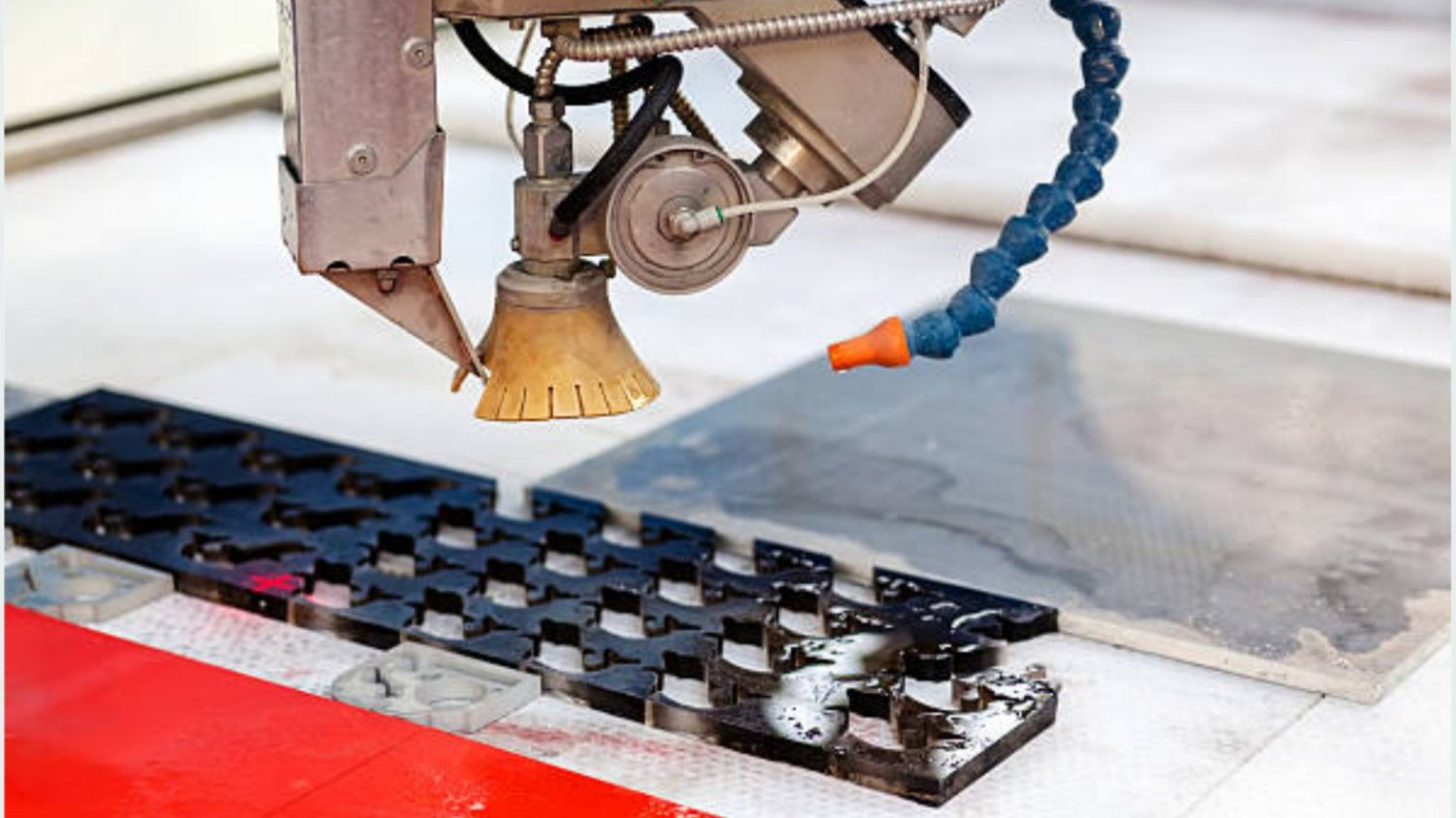

The Mold Making Process

The mold making process begins with the creation of a mold or pattern that will be used to shape the final product. The mold is typically made from a material such as wood, metal, or silicone. Once the mold is created, it is filled with the chosen material, such as plastic or metal, and allowed to cool or cure. Once the material has hardened, the mold is removed, and the final product is ready for use.

The Importance of Precision in Mold Component Manufacturing

Precision is critical in mold component manufacturing because even small deviations can lead to defects or failures in the final product. Manufacturers use a variety of tools and techniques to ensure that the molds and components they produce are accurate and consistent. This includes computer-aided design (CAD) software, precision measurement tools, and specialized manufacturing equipment.

Quality Control in Mold Component Manufacturing

Quality control is a critical component of mold component manufacturing. Manufacturers employ a variety of techniques to ensure that the molds and components they produce meet the desired specifications. This includes regular inspections, testing, and calibration of manufacturing equipment.

Applications of Mold Component Manufacturing

Mold component manufacturing is used in a wide variety of applications, from the production of toys and consumer goods to medical devices and aerospace components. The process is particularly well-suited for mass production of products that require high levels of precision and consistency.

The Future of Mold Component Manufacturing

The future of mold component manufacturing is bright. Advances in technology are making the process more efficient and cost-effective than ever before. This includes the use of 3D printing, automation, and advanced materials. As demand for high-quality, reliable products continues to grow, mold component manufacturing will remain a critical component of many industries.

The Role of Sustainability in Mold Component Manufacturing

Sustainability is becoming an increasingly important consideration in mold component manufacturing. Manufacturers are looking for ways to reduce waste, conserve energy, and minimize their environmental impact. This includes the use of recycled materials, energy-efficient manufacturing processes, and sustainable packaging solutions.

The Importance of Innovation in Mold Component Manufacturing

Innovation is critical in mold component manufacturing. The industry is constantly evolving, and manufacturers must continually adapt to stay competitive. This includes the development of new materials and processes, the use of advanced manufacturing techniques, and the adoption of emerging technologies.

Conclusion

Mold component manufacturing is a critical industry that plays an important role in the production of many consumer goods. The process requires a high degree of precision and attention to detail to ensure that the final product is both functional and aesthetically pleasing. As demand for high-quality, reliable products continues to grow, mold component manufacturing will remain a vital component of many industries.