The Key Benefits of CNC Machining

Increased Efficiency and Accuracy

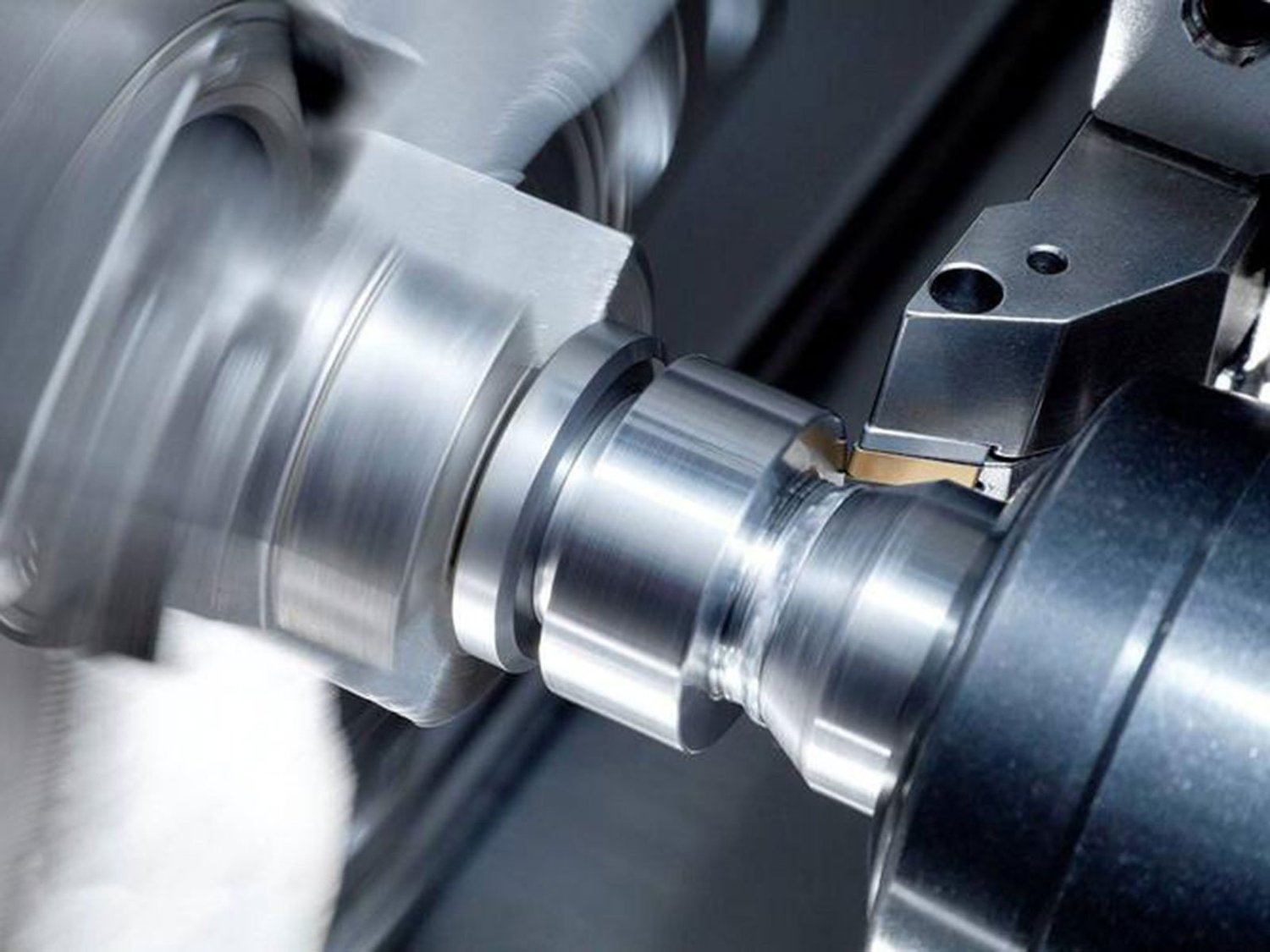

CNC (Computer Numerical Control) machining is a highly advanced manufacturing process that utilizes computerized controls to operate and manipulate machine tools, resulting in increased efficiency and accuracy. Unlike traditional manual machining, CNC machining eliminates the need for human intervention during the production process, allowing for precise and consistent results.

Enhanced Safety

One of The Key Benefits of CNC Machining is the increased level of safety it provides. With automated operations, there is a reduced risk of human error and associated accidents. Additionally, CNC machines are equipped with various safety mechanisms, such as emergency stop buttons and safety interlocks, ensuring a safe working environment for operators.

Cost Savings

CNC machining offers significant cost savings in the long run. While the initial investment in CNC machines may be higher compared to traditional machines, the overall operational costs are lower. With precise cutting and reduced material wastage, CNC machining helps minimize raw material expenses. Moreover, the automation of processes leads to reduced labor costs and increased productivity.

Higher Production Capacity

By utilizing CNC machining, manufacturers can achieve higher production capacity. Compared to manual machining, CNC machines can operate continuously for extended periods, with minimal downtime for maintenance or tool changes. This allows for increased production output and shorter lead times, meeting customer demands more efficiently.

Consistent Quality

CNC machining ensures consistent quality in every production batch. The computerized controls of CNC machines provide precise and repeatable movements, resulting in uniform product dimensions and surface finishes. This consistency is particularly crucial in industries where strict adherence to specifications is required, such as aerospace or medical.

Wide Range of Materials

CNC machining can work with a wide range of materials, including metals, plastics, composites, and even certain types of wood. This versatility makes it a preferred choice in various industries, allowing manufacturers to create complex and intricate parts from different materials. Whether it's aluminum, stainless steel, or engineering plastics, CNC machining can handle them all.

Flexibility and Customization

CNC machining offers unparalleled flexibility and customization options. With computer programming, manufacturers can easily modify and adapt the design specifications, allowing for quick changes or adjustments to meet specific requirements. This flexibility is particularly beneficial in industries where rapid prototyping or small batch production is common.

Improved Time-to-Market

For businesses looking to bring products to market quickly, CNC machining offers a significant advantage. The automation and precision of CNC machines eliminate time-consuming manual operations, resulting in faster turnaround times. With reduced lead times, manufacturers can respond promptly to market demands and gain a competitive edge.

Higher Productivity and Reduced Lead Times

CNC machining significantly improves productivity and reduces lead times. The automated nature of CNC machines allows for uninterrupted operations, maximizing production output. Additionally, the elimination of manual intervention reduces the risk of errors and delays, ensuring faster completion of projects and timely delivery to customers.

Sustainability and Waste Reduction

CNC machining promotes sustainability and waste reduction. By precisely cutting materials, CNC machines minimize material wastage, optimizing the use of raw materials. This not only reduces costs but also contributes to a more sustainable manufacturing process. Furthermore, CNC machining generates less scrap, resulting in decreased environmental impact.