The Prospects of Mold Engraving: A Comprehensive Guide

Mold engraving is the process of carving intricate designs onto a mold that will be used for manufacturing a product. It is a crucial process in many industries, particularly in the plastic industry. In this article, we will take you through the prospects of mold engraving and how it enhances manufacturing processes.

The Importance of Mold Engraving

Mold engraving is essential in creating the unique designs that many products require. It involves the use of specialized equipment to create grooves, lines, and textures on molds that give products their distinctive looks and features. Without mold engraving, many products would be plain and uniform, with no defining or distinguishing characteristics.

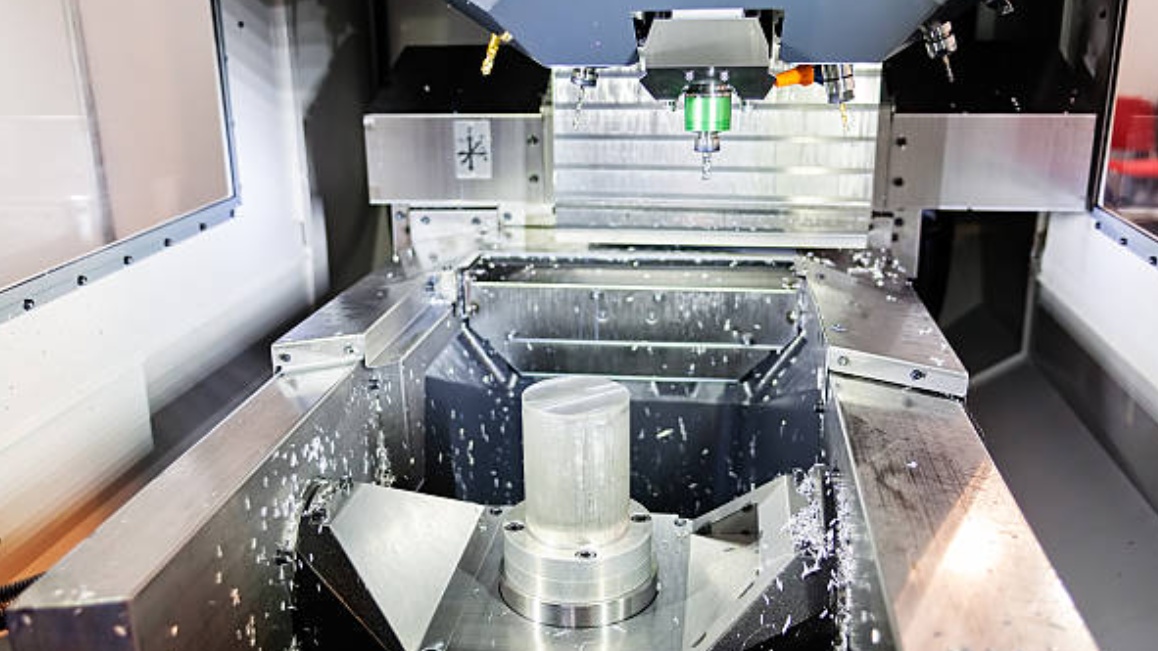

The Process of Mold Engraving

Mold engraving is a delicate and intricate process that requires skilled professionals to carry out. The process begins with the creation of a 3D model of the desired pattern. This model is then transferred onto the mold using specialized engraving tools, which cut away material to create the desired pattern. The process is time-consuming, but the final product is always worth it.

The Benefits of Mold Engraving

Mold engraving has several benefits, including:

- Enhancing the aesthetic appeal of products by creating unique designs

- Improving functionality by incorporating features that improve product performance

- Reducing costs by increasing the efficiency of manufacturing processes

The Role of Mold Engraving in Product Development

Product development is a crucial process that involves several steps, with mold engraving being one of the most important. Mold engraving determines the appearance and functionality of the final product, which is why it is essential to get it right. Skilled professionals work hard to ensure that the patterns created on molds meet the design specs and the expected outcome.

The Different Types of Mold Engraving

There are several types of mold engraving techniques, including:

- Laser engraving

- Manual engraving

- CNC engraving

- Rotary engraving

Mold Engraving and Quality Control

Mold engraving is a crucial aspect of quality control during the manufacturing process. It ensures that products meet the design specs, have no defects, and meet the quality standards required by customers. Through mold engraving, manufacturers can guarantee that their products are aesthetically pleasing, perform well, and meet customer expectations.

The Future of Mold Engraving

The future of mold engraving looks bright, with innovative technologies emerging that promise to enhance the process even further. New engraving techniques are being developed that promise to reduce costs, improve efficiency, and increase the quality of the final product. With these innovations, mold engraving will continue to play a vital role in manufacturing processes for years to come.

Choosing the Right Mold Engraving Service Provider

Choosing the right mold engraving service provider is essential for ensuring that products meet the expected quality standards. It is crucial to choose a service provider with experience, expertise, and a proven track record of delivering high-quality results. A good mold engraving service provider will work closely with the client to understand their needs and ensure that the final product meets their specifications.

The Cost of Mold Engraving Services

The cost of mold engraving services varies depending on several factors, including the complexity of the pattern, the size of the mold, and the number of molds required. It is essential to get quotes from several service providers and compare prices before selecting one. Generally, mold engraving services are worth the investment due to the enhanced value they add to the final product.

In Conclusion

Mold engraving is a crucial process in product development and manufacturing. It enhances the aesthetic appeal and functionality of products and plays a vital role in quality control. Its future looks promising, with innovative technologies promising to improve efficiency and reduce costs even further. Choosing the right service provider is essential for ensuring high-quality results, and the investment is worth the enhanced value it adds to the final product.