Introduction

CNC (Computer Numerical Control) technology has revolutionized the manufacturing industry, transforming traditional manual processes into precise and automated ones. One such process is CNC Engraving, which has numerous advantages for businesses looking to expand their product offerings and cater to customer demands. In this article, we will discuss the top 10 benefits of CNC engraving:

1. Precision and Accuracy

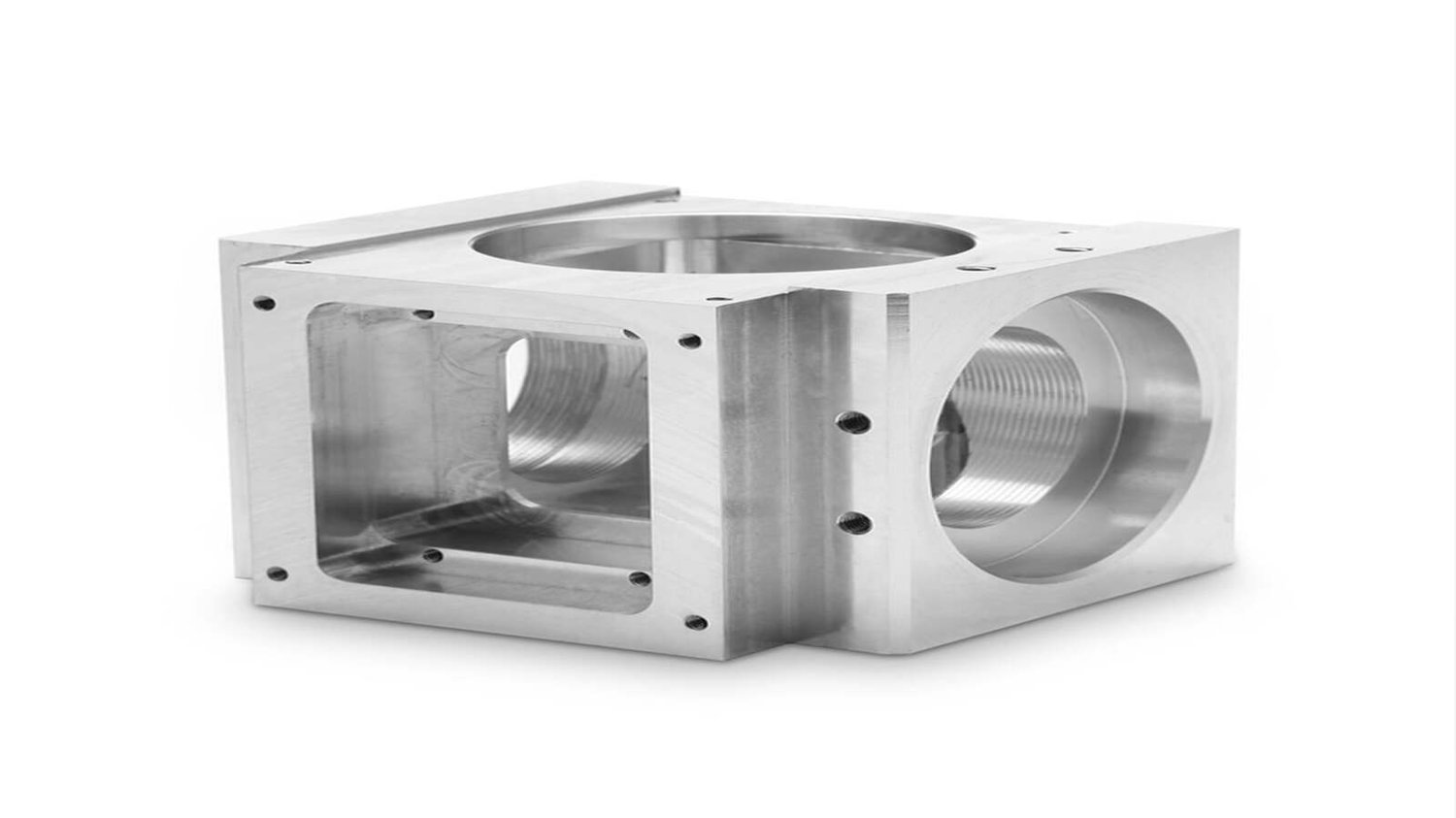

CNC engraving machines use advanced software to precisely and accurately cut and engrave materials such as wood, metal, and plastic. This eliminates the possibility of human error, ensuring that each product is of consistent quality and meets exact specifications.

2. Speed and Efficiency

CNC engraving machines can work around the clock, greatly increasing production capacity and reducing lead times. They also require minimal supervision, allowing personnel to operate more machines or focus on other value-added tasks.

3. Flexibility and Customization

CNC engraving machines can be programmed to engrave a wide variety of designs and patterns, including logos, text, and images. This makes them ideal for creating unique, personalized products that cater to individual customer preferences.

4. Cost-Effective

CNC engraving reduces labor costs, as fewer personnel are needed to operate and oversee the machines. It also minimizes material waste and ensures that materials are used efficiently, leading to lower overall production costs.

5. Versatility

CNC engraving machines can be used to engrave a wide variety of materials, including wood, metal, plastic, and glass. This makes them ideal for a wide range of industries, including manufacturing, signage, and woodworking.

6. Consistency and Replicability

CNC engraving machines can create precise replicas of products, ensuring that each customer receives the same high-quality product every time. This can help build brand recognition and loyalty, as customers come to rely on the consistency and quality of your products.

7. Reduced Risk of Injury

CNC engraving machines are designed to operate safely and efficiently, with safety features such as automatic shut-off and sensors that detect anomalies. This reduces the risk of personnel injury, ensuring a safe working environment for all employees.

8. Minimal Maintenance

CNC engraving machines require minimal maintenance, as they are designed to operate continuously with minimal downtime. This reduces maintenance costs and ensures that the machines are always ready to produce high-quality products.

9. Increased Profit Margins

CNC engraving machines offer higher profit margins, as they reduce labor, material, and maintenance costs while increasing production capacity and product quality. This allows businesses to remain competitive in the market and increase their profitability.

10. Future-Proof Investment

CNC engraving machines are a future-proof investment, as they are designed to keep up with technological advancements and changing industry demands. They can be programmed to incorporate new features and ensure that your business stays ahead of the competition.

Conclusion

CNC engraving machines offer numerous benefits for businesses looking to improve their production capacity, quality, and profitability. By investing in a CNC engraving machine, businesses can reduce costs, increase customization and flexibility, and stay ahead of the competition in a rapidly evolving market.