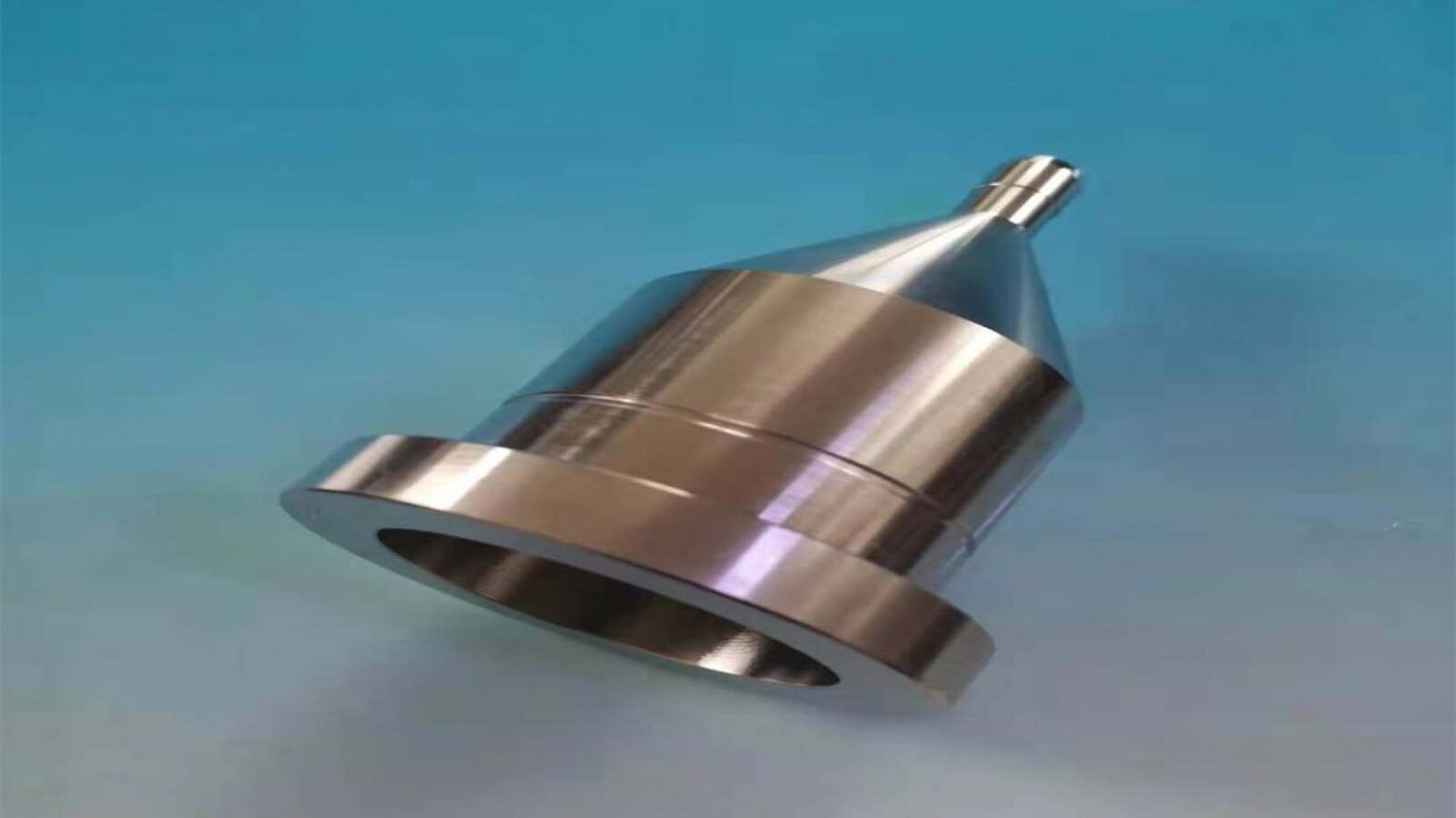

What is Numerical Control Machining? Numerical Control Machining, also known as CNC machining, is a manufacturing process where pre-programmed computer software dictates the movement of machinery and tools. This technology allows for precise and efficient production of complex parts and components.

The History of Numerical Control Machining Numerical Control Machining has its roots in the 1940s when John T. Parsons collaborated with the Massachusetts Institute of Technology to develop a system that controlled the movements of a machine tool. This marked the beginning of a revolution in the manufacturing industry.

The Benefits of Numerical Control Machining One of the main advantages of Numerical Control Machining is its precision. With CNC technology, manufacturers can achieve extremely tight tolerances and produce intricate designs that would be impossible with manual machining. Additionally, CNC machines can operate 24/7, leading to faster production times and increased efficiency.

The Applications of Numerical Control Machining Numerical Control Machining is used across a wide range of industries, including aerospace, automotive, and electronics. CNC machines are capable of producing everything from simple components to complex prototypes with high levels of accuracy and consistency.

The Types of Numerical Control Machining There are several different types of Numerical Control Machining processes, including milling, turning, and laser cutting. Each type of CNC machine is designed for specific applications and can produce a variety of shapes and sizes with precision and speed.

The Future of Numerical Control Machining As technology continues to advance, so too does Numerical Control Machining. The integration of artificial intelligence and automation in CNC machines is revolutionizing the industry, allowing for even greater levels of precision, efficiency, and cost-effectiveness.

The Environmental Impact of Numerical Control Machining Numerical Control Machining is considered to be a more environmentally friendly manufacturing process compared to traditional methods. CNC machines produce less waste, consume less energy, and have a smaller carbon footprint, making them a sustainable choice for companies looking to reduce their impact on the environment.

The Training and Skills Required for Numerical Control Machining Operating and programming CNC machines requires specialized training and skills. Individuals in this field must have a solid understanding of computer-aided design (CAD) software, as well as knowledge of machining techniques and materials. Ongoing training is essential to stay current with the latest advancements in CNC technology.

The Cost Considerations of Numerical Control Machining While Numerical Control Machining offers numerous benefits, it can also be a significant investment for companies. The cost of CNC machines, software, and training can vary depending on the complexity of the equipment and the level of expertise required. Companies must carefully consider these factors when implementing CNC technology.

The Future Outlook for Numerical Control Machining With its precision, efficiency, and versatility, Numerical Control Machining is poised to play a crucial role in the future of manufacturing. As technology continues to evolve, CNC machines will become increasingly advanced, allowing for the production of even more complex and innovative products.