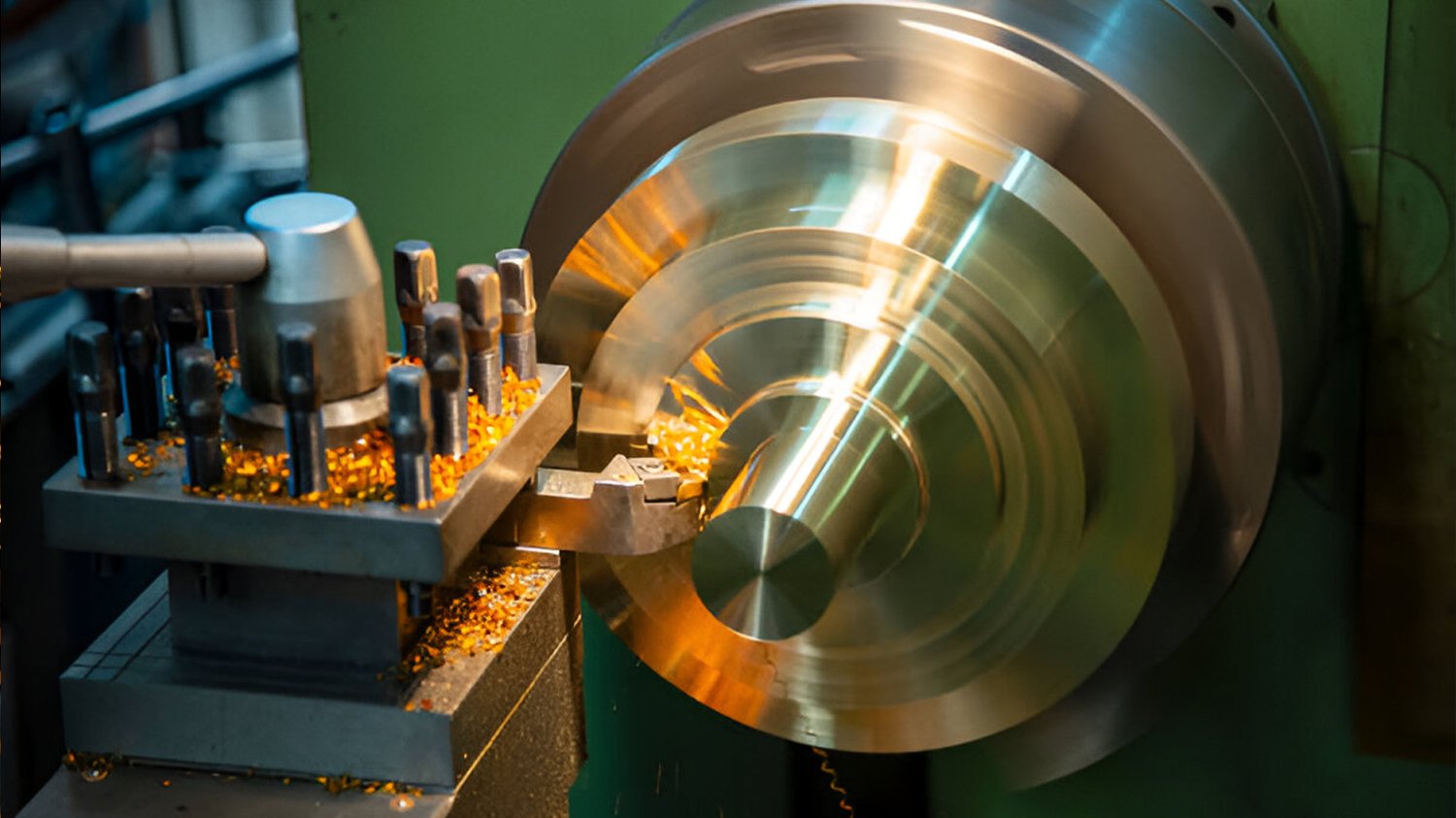

What is Surface treatment machining?

Surface treatment machining is a process that involves modifying the surface properties of a material or component, usually to improve its performance or appearance. This can be achieved through various methods, including applying coatings, etching, polishing, and blasting. In this article, we will take a closer look at surface treatment machining and its different aspects.

The Importance of Surface Treatment Machining

Surface treatment machining plays a vital role in various industries, including automotive, aerospace, and medical. By altering the surface properties of a material or component, it can enhance its resistance to wear, corrosion, and other forms of degradation. It can also improve its aesthetics, making it more visually appealing to customers.

The Different Methods of Surface Treatment Machining

There are several methods of surface treatment machining, including:

- Coatings: This involves depositing a thin layer of a substance onto the surface of a material to improve its properties. Common coating materials include metals, ceramics, and polymers. Examples of coating processes include electroplating, chemical vapor deposition, and thermal spray.

- Etching: Etching involves selectively removing material from a surface using acids or other chemicals. This can be used to create patterns, textures, or to remove surface contaminants.

- Polishing: Polishing involves using abrasive compounds or pads to smooth a surface and improve its reflectivity. This is commonly used in the manufacturing of optical components and mirrors.

- Blasting: Blasting involves using abrasive particles to clean or roughen a surface. This can be used to remove rust, paint, or other coatings, as well as to create a rough surface for better adhesion of coatings.

The Benefits of Surface Treatment Machining

The benefits of surface treatment machining include:

- Improved durability: Surface treatment machining can improve a material's resistance to wear, corrosion, and other forms of degradation, extending its lifespan.

- Enhanced aesthetics: Surface treatment machining can improve the appearance of a component, making it more visually appealing to customers.

- Better performance: Surface treatment machining can improve a component's performance, such as reducing friction or enhancing electrical conductivity.

- Reduced costs: Surface treatment machining can reduce costs by extending the lifespan of components and reducing the need for maintenance or replacement.

The Applications of Surface Treatment Machining

Surface treatment machining has many applications in various industries, including:

- Automotive: Surface treatment machining is used to improve the durability and appearance of car components, such as engine parts, wheels, and bodywork.

- Aerospace: Surface treatment machining is used to improve the performance and durability of aircraft components, such as turbine blades and landing gear.

- Medical: Surface treatment machining is used to improve the biocompatibility and corrosion resistance of medical implants and devices.

- Electronics: Surface treatment machining is used to improve the electrical conductivity and corrosion resistance of electronic components, such as circuit boards and connectors.

The Future of Surface Treatment Machining

The field of surface treatment machining is constantly evolving, with new technologies and techniques being developed. One area of focus is nanotechnology, which involves manipulating matter at the nanoscale level to create new materials with unique properties. Another area of focus is eco-friendly surface treatment methods, which aim to reduce the use of harmful chemicals and waste in the process.

Choosing the Right Surface Treatment Method

Choosing the right surface treatment method depends on several factors, including the material being treated, the desired properties, the environment the component will be used in, and the cost. It is important to consult with an expert to determine the most appropriate method for your application.

Conclusion

Surface treatment machining is an essential process for improving the performance and appearance of materials and components in various industries. By understanding the different methods and benefits of surface treatment machining, you can make informed decisions and choose the right method for your application.