The Advantages of CNC Machining over Traditional Manufacturing Methods

Introduction

Manufacturing methods have evolved significantly over the years, and one technology that has revolutionized the industry is CNC machining. In this article, we will explore the reasons why CNC machining is a superior choice compared to traditional manufacturing methods.

Precision and Accuracy

One of the primary advantages of CNC machining is its unmatched precision and accuracy. Unlike traditional manufacturing methods that rely on manual labor, CNC machines are controlled by computer programs, ensuring consistent and precise results every time. This level of precision is crucial in industries such as aerospace, medical, and automotive, where even the smallest deviations can have significant consequences.

Increased Efficiency

CNC machining offers a tremendous boost in efficiency compared to traditional manufacturing methods. With CNC machines, complex tasks can be automated, reducing the need for manual labor. This not only saves time but also minimizes the chances of human error. Additionally, CNC machines can operate 24/7, significantly increasing production output and reducing lead times.

Flexibility and Versatility

CNC machines offer unparalleled flexibility and versatility in manufacturing. Unlike traditional manufacturing methods that require specific tools and setups for each product, CNC machines can easily be reprogrammed to produce different parts or products. This level of flexibility is particularly advantageous for small-batch production, prototyping, and customization.

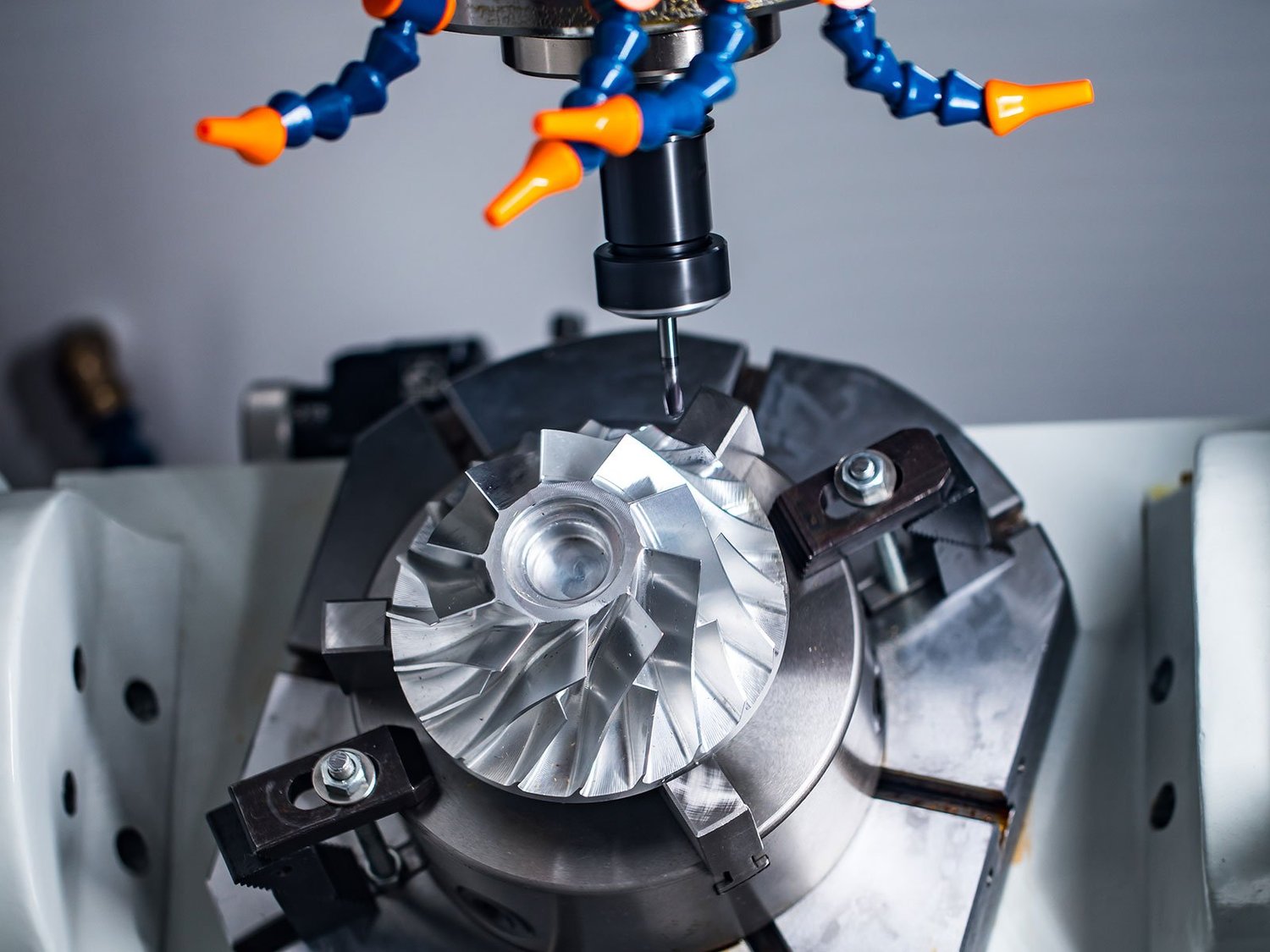

Complex Geometries Made Easy

Manufacturing complex geometries can be a challenging task using traditional methods. CNC machining, on the other hand, excels in producing intricate shapes and designs with ease. By utilizing advanced CAD/CAM software, designers can create complex 3D models that can be directly translated into CNC machine instructions, resulting in accurate and precise production of complex parts.

Consistency and Reproducibility

Consistency and reproducibility are essential factors in manufacturing. CNC machining ensures that each part produced is identical to the previous one, regardless of the batch size. This level of consistency is crucial in industries that require interchangeable parts or components that need to fit together precisely.

Reduced Labor Costs

Traditional manufacturing methods often require a significant amount of manual labor, which can be both time-consuming and costly. CNC machining drastically reduces labor costs by automating various manufacturing processes. With CNC machines, a single operator can oversee multiple machines simultaneously, reducing the need for a large workforce.

Improved Safety

CNC machining offers improved safety compared to traditional manufacturing methods. By automating processes and minimizing human involvement, the risk of accidents and injuries is significantly reduced. CNC machines also have built-in safety features, such as emergency stop buttons and sensors, further enhancing workplace safety.

Faster Prototyping

Prototyping is an essential phase in product development, and CNC machining excels in this area. By utilizing CAD software, designers can quickly create prototypes and test their functionality before moving to mass production. CNC machines can rapidly produce prototypes with high precision, allowing for faster iterations and ultimately reducing time to market.

Cost-Effective for Small Production Runs

For small production runs, CNC machining proves to be highly cost-effective compared to traditional methods. The ability to quickly reprogram CNC machines and produce small quantities without the need for expensive tooling or setup changes makes it an ideal choice for businesses looking to minimize costs and maximize profits.