The Basics of Wire Cutting Erosion

Wire cutting erosion is a machining process that is used to cut intricate shapes and designs into various materials. It is a highly precise method that can be used on materials such as metal, plastic, and even hard materials like ceramics. This article will explore the different aspects of wire cutting erosion, including its applications, advantages, and limitations.

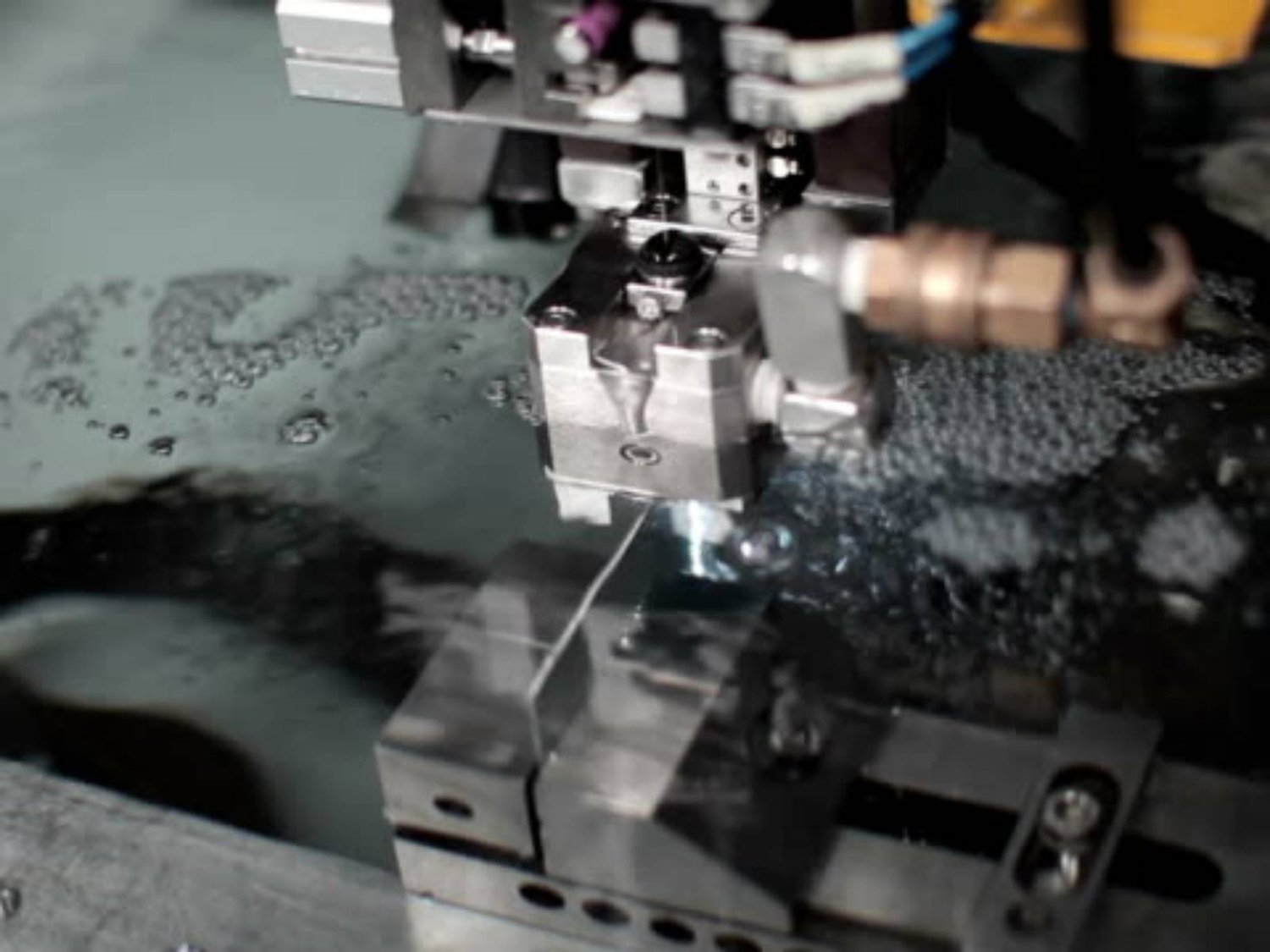

How Wire Cutting Erosion Works

Wire cutting erosion, also known as wire EDM (Electrical Discharge Machining), operates by using a thin, electrically charged wire to cut through the material. The wire is guided along a programmed path, controlled by a computer, while a dielectric fluid is used to flush away the eroded material. The wire carries an electric current that creates a spark discharge, which melts the material it comes into contact with. This process allows for highly precise cuts, with tolerances as small as 0.001mm.

The Applications of Wire Cutting Erosion

Wire cutting erosion has a wide range of applications across various industries. One of the most common uses is in the manufacturing of dies and molds for industries such as automotive, aerospace, and electronics. It is also utilized in the creation of intricate parts and components for medical devices, jewelry, and even in the production of printed circuit boards. The ability of wire cutting erosion to cut complex shapes and designs makes it a valuable tool in many industries.

The Advantages of Wire Cutting Erosion

Wire cutting erosion offers several advantages over other machining methods. Firstly, it allows for the cutting of complex shapes and designs that would be difficult or impossible to achieve with traditional machining techniques. It also provides high precision and accuracy, ensuring that the final product meets the required specifications. Additionally, wire cutting erosion is a non-contact process, which means there is no physical force exerted on the material, reducing the risk of distortion or damage.

The Limitations of Wire Cutting Erosion

While wire cutting erosion is a highly effective machining process, it does have some limitations. One of the main drawbacks is the slow cutting speed compared to other methods. This is due to the nature of the process, as each cut requires the wire to pass through the material, resulting in a slower overall production rate. Additionally, wire cutting erosion is not suitable for materials that are highly conductive, such as copper or aluminum, as they can cause excessive wire wear.

Factors Affecting Wire Cutting Erosion

Several factors can influence the effectiveness of wire cutting erosion. The material being cut plays a significant role, as different materials have varying levels of hardness and conductivity. The thickness of the material can also affect the cutting speed and accuracy. The wire used in the process, including its diameter and material composition, can impact the precision of the cuts. Finally, the choice of dielectric fluid and its properties, such as viscosity and flushing capability, can influence the overall performance of the process.

The Importance of Wire Cutting Erosion in Precision Engineering

Wire cutting erosion plays a crucial role in precision engineering, where accuracy and intricate designs are paramount. The ability to create complex shapes and precise cuts allows for the production of high-quality components and parts. In industries such as aerospace and medical devices, where safety and reliability are critical, wire cutting erosion enables the manufacturing of intricate and reliable parts that meet strict quality standards.

The Future of Wire Cutting Erosion

As technology continues to advance, wire cutting erosion is also evolving. Improvements in machine design, control systems, and wire materials are constantly being made to enhance the efficiency and precision of the process. Additionally, the use of wire cutting erosion in combination with other manufacturing methods, such as 3D printing, opens up new possibilities for creating complex and customized components. The future of wire cutting erosion looks promising, with its continued relevance in precision engineering.

Conclusion

Wire cutting erosion is a highly precise machining process that offers numerous benefits in the manufacturing industry. Its ability to cut complex shapes and designs, along with its accuracy and reliability, make it an invaluable tool for producing high-quality components. While it does have some limitations, the advancements in technology and material research continue to improve the efficiency and capabilities of wire cutting erosion. As industries continue to demand intricate and precise parts, wire cutting erosion will undoubtedly play a significant role in the future of manufacturing.