Wire cutting machining, also known as wire EDM or CNC wire cutting, is a precision cutting technology that uses an electrically charged wire to cut through hardened materials. The wire is guided by a computer-controlled machine to create intricate shapes and designs with minimal waste and maximum accuracy. This article will delve into the various aspects of wire cutting machining, from its history and development to its applications and advantages.

The Origins of Wire Cutting Machining

The origins of wire cutting machining date back to the 1960s, when it was first introduced as a tool for cutting and shaping hardened metal parts. It was initially used in the aerospace and defense industries, where precision was a critical factor. Over time, advances in technology and software have made wire cutting machining faster, more reliable, and more accessible to industries such as medical device manufacturing, automotive engineering, and consumer goods production.

How Wire Cutting Machining Works

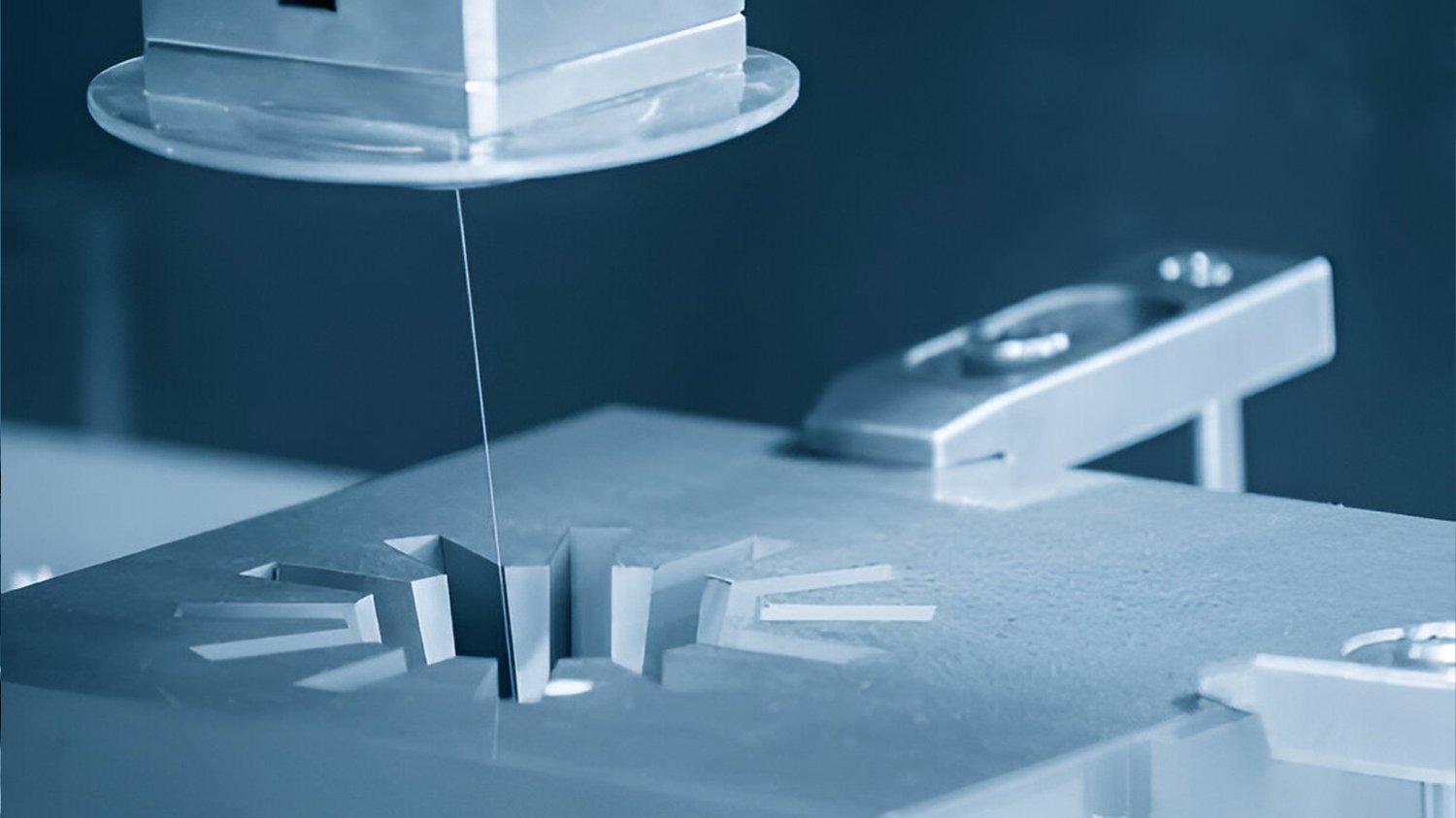

Wire cutting machining uses a thin wire, typically made of brass or tungsten, to cut through materials that would be impossible to cut with a traditional saw or blade. The wire is held taut between two spools and passed through the material to be cut, while an electrical current is used to erode the material's surface. The wire is guided by computer-controlled software, allowing for precise cuts and consistent results. The resulting cut is clean and precise with minimal burrs or rough edges.

The Advantages of Wire Cutting Machining

Wire cutting machining offers numerous advantages over traditional cutting methods. Firstly, it can cut through materials that would be difficult or impossible to cut with other tools, such as hardened steel, titanium, and nickel. Secondly, it creates very little waste, as the wire is barely worn down or deformed during the cutting process. Finally, wire cutting machining produces highly precise cuts, which reduces the need for post-processing and ensures a high degree of accuracy in the finished product.

The Applications of Wire Cutting Machining

Wire cutting machining has found a home in a wide range of industries. It is particularly useful in industries that require precision parts or components, such as medical device manufacturing, aerospace engineering, and automotive production. It can also be used for more artistic applications, such as creating jewelry or other intricate designs. In general, if an industry requires precision cuts, wire cutting machining is a reliable and cost-effective choice.

The Different Types of Wire Cutting Machining

There are several different types of wire cutting machining that can be used depending on the specific application. These include:

- Standard wire cutting, which uses a single wire to cut through the material.

- Multistrand wire cutting, which uses multiple wires to cut through thicker materials.

- Abrasive wire cutting, which employs a wire coated in abrasive particles to cut harder materials.

- Submerged wire cutting, which uses a wire submerged in a dielectric fluid to improve cutting efficiency and accuracy.

The Limitations of Wire Cutting Machining

While wire cutting machining has numerous advantages, it is not suitable for all applications. For example, it may not be cost-effective for low-volume production or for materials that can be easily cut with other tools. Additionally, it is not suitable for cutting complex shapes or curves, as it requires a straight, continuous cut. Finally, wire cutting machining tends to be slower than other cutting technologies, which can impact production timelines and costs.

The Costs of Wire Cutting Machining

The costs of wire cutting machining vary depending on a range of factors, including the type of wire used, the level of precision required, and the volume of parts ordered. However, wire cutting machining is generally considered to be a cost-effective option for producing high-quality, precision parts. The minimal waste and high degree of accuracy translate into savings in material costs, labor costs, and post-processing costs.

The Future of Wire Cutting Machining

Wire cutting machining is a mature technology that has been in use for several decades. However, as with any technology, there is always room for improvement and innovation. In the future, advances in wire materials, automation, and software are likely to make wire cutting machining even more efficient, precise, and accessible. As a result, it is likely that we will continue to see wire cutting machining used in a wide variety of applications and industries for many years to come.