Digital Machining

100,000 collaborative factories��Whether you need assistance with prototyping, production, or sourcing, our platform offers a comprehensive solution to meet all your manufacturing needs.

One-stop service, turnkey project service: We provide end-to-end solutions, managing every aspect of projects from start to finish.

Design team, technical team: Our experts in design and technology collaborate to deliver innovative and meticulously crafted products.

Digital Machining: The Cutting-Edge Solution for Precision Engineering

Are you in search of a revolutionary technology that will take your machining capabilities to new heights? Look no further than Digital Machining, the ultimate solution for precision engineering. With its state-of-the-art features and unmatched accuracy, Digital Machining is designed to revolutionize the manufacturing industry. Read on to discover how this cutting-edge technology can transform your business.

Enhanced Efficiency and Accuracy

At the heart of Digital Machining lies its ability to deliver unparalleled efficiency and accuracy. Through its advanced digital control system, this technology ensures precise movements and positioning, eliminating any room for human error. With Digital Machining, you can achieve intricate designs and complex shapes with utmost precision, resulting in products of exceptional quality.

Seamless Integration and User-Friendly Interface

One of the standout features of Digital Machining is its seamless integration with existing manufacturing processes. Whether you are a small-scale workshop or a large-scale production facility, this technology can easily be incorporated into your workflow. The user-friendly interface allows operators to quickly adapt to the system, reducing downtime and maximizing productivity.

Unmatched Versatility and Flexibility

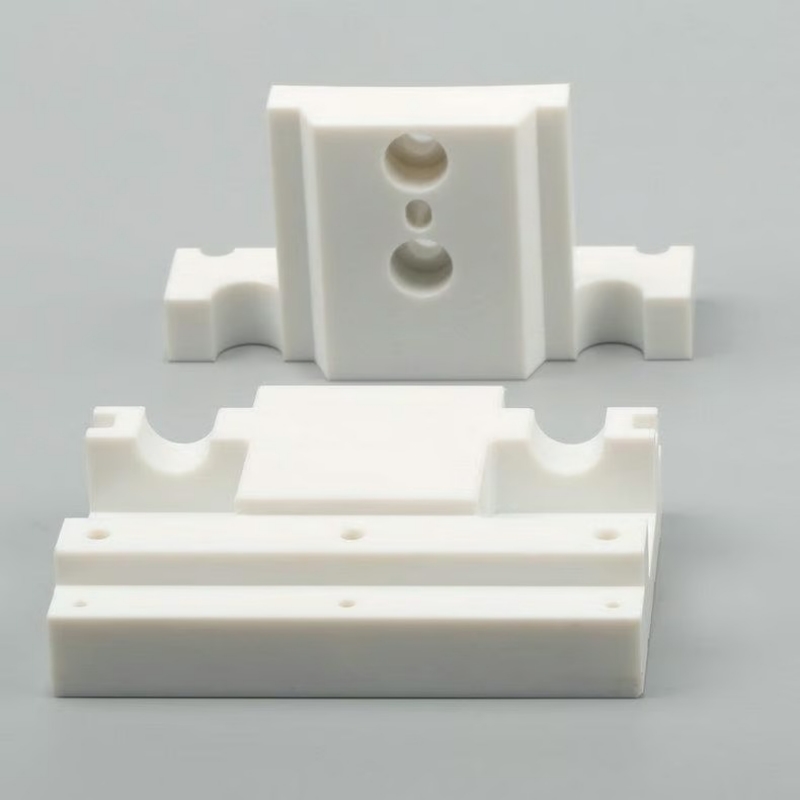

With Digital Machining, you can say goodbye to the limitations of traditional machining methods. This cutting-edge technology offers unmatched versatility and flexibility, allowing you to work with a wide range of materials, including metals, plastics, and composites. Whether you need to create prototypes, produce intricate components, or perform complex machining operations, Digital Machining is your go-to solution.

Real-Time Monitoring and Quality Control

Quality control is of utmost importance in any manufacturing process, and Digital Machining ensures that you are always in control. Its real-time monitoring capabilities allow you to track and analyze every aspect of the machining process, ensuring adherence to the highest quality standards. With Digital Machining, you can detect and correct any issues before they impact the final product, saving you time and resources.

Increased Productivity and Cost Savings

When it comes to manufacturing, time is money. Digital Machining helps you optimize your production process, resulting in increased productivity and significant cost savings. By automating repetitive tasks and minimizing human intervention, this technology enables you to streamline your operations and reduce lead times. With Digital Machining, you can meet tight deadlines without compromising on quality.

Advanced Cutting Tools and Techniques

Digital Machining is equipped with advanced cutting tools and techniques that push the boundaries of traditional machining. From high-speed machining to multi-axis milling, this technology offers a wide range of capabilities to meet your specific requirements. With Digital Machining, you can achieve complex geometries, smooth surface finishes, and intricate details that were once thought impossible.

Seamless Integration with CAD/CAM Software

Efficiency and accuracy are further enhanced through the seamless integration of Digital Machining with CAD/CAM software. This integration allows for seamless transfer of design data, eliminating the need for manual programming and reducing the risk of errors. With Digital Machining, you can bring your digital designs to life with ease, ensuring a smooth transition from concept to reality.

Future-Proof Technology with Upgradable Features

Investing in Digital Machining means investing in the future. This technology is designed to evolve with your needs, with upgradable features that keep you at the forefront of innovation. As new advancements are made, you can easily integrate them into your existing system, ensuring that your capabilities remain cutting-edge. With Digital Machining, you can future-proof your business and stay ahead of the competition.

Unrivaled Customer Support and Training

When you choose Digital Machining, you gain access to unrivaled customer support and training. Our team of experts is dedicated to ensuring your success, providing comprehensive training programs and ongoing assistance. Whether you need technical support, guidance in optimizing your processes, or advice on maximizing your return on investment, our team is here to help. With Digital Machining, you can trust that you are not just investing in a product, but in a long-term partnership.

Certificates

With a strong foothold in the Machinery manufacturing industry, we proudly showcase an array of industry certificates that validate our commitment to excellence. These certificates, earned over the years, stand as a testament to our unwavering dedication to producing highly competitive products. By adhering to stringent quality standards and employing cutting-edge technology, we consistently deliver superior machinery that exceeds customer expectations. Our advantage lies in our ability to seamlessly integrate innovation with reliability, ensuring our products are at the forefront of the industry. We prioritize customer satisfaction by offering tailored solutions, exceptional after-sales service, and a responsive support team. Our competitive pricing, coupled with our unwavering commitment to delivering on time, further distinguishes us from the competition. Trust in our expertise, bolstered by our industry certificates, and experience the unparalleled advantages we bring to the Machinery manufacturing industry.