Automated Tooling

100,000 collaborative factories��Whether you need assistance with prototyping, production, or sourcing, our platform offers a comprehensive solution to meet all your manufacturing needs.

One-stop service, turnkey project service: We provide end-to-end solutions, managing every aspect of projects from start to finish.

Design team, technical team: Our experts in design and technology collaborate to deliver innovative and meticulously crafted products.

Efficiency and Precision: Automated Tooling for Streamlined Operations

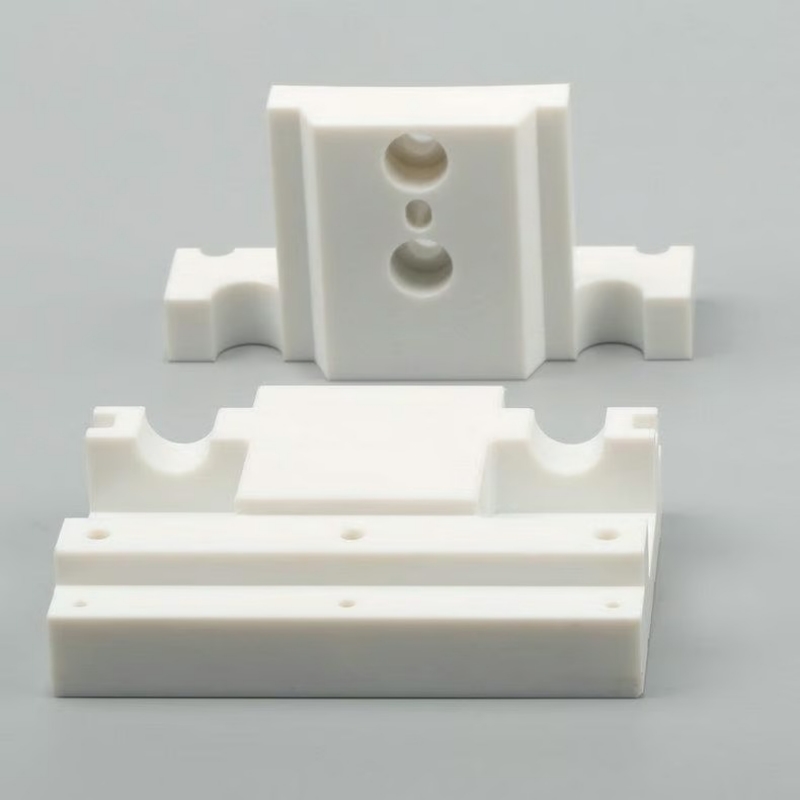

Automated Tooling is a cutting-edge solution for businesses seeking to optimize their manufacturing processes. With its advanced technology and innovative features, this state-of-the-art tooling system offers unparalleled efficiency and precision. By automating various tasks, it significantly reduces production time while ensuring consistent quality. Whether you are a small-scale workshop or a large-scale industrial facility, Automated Tooling is the answer to your productivity needs.Seamless Integration and User-Friendly Interface

One of the key advantages of Automated Tooling is its seamless integration into existing manufacturing setups. This versatile system is compatible with a wide range of machinery and can be easily incorporated into your production line. Its user-friendly interface allows operators of all skill levels to navigate and control the system effortlessly. The intuitive design ensures minimal training requirements and maximum productivity from day one.Enhanced Safety and Reduced Risk

Safety is of paramount importance in any industrial environment. Automated Tooling prioritizes safety by minimizing human intervention and reducing the risk of accidents. With its advanced sensors and built-in safety protocols, this tooling system ensures that operations run smoothly without endangering the well-being of your workforce. By automating hazardous tasks, it provides a safer working environment and decreases the likelihood of workplace injuries.Precision Engineering for Exceptional Quality

Automated Tooling is renowned for its precision engineering, guaranteeing exceptional quality in every product manufactured. The system's precise measurements and accurate machining capabilities result in consistent output, eliminating variations and defects. This level of precision ensures that your products meet the highest industry standards, enhancing your reputation and customer satisfaction.Effortlessly Boost Production Capacity

With Automated Tooling, businesses can effortlessly increase their production capacity. By automating various production tasks, the system eliminates human limitations and significantly speeds up the manufacturing process. This allows you to meet higher demand, fulfill orders more efficiently, and ultimately increase your profitability. Automated Tooling empowers you to scale your operations without compromising on quality or customer satisfaction.Real-Time Monitoring and Data Analysis

Stay in control of your manufacturing process with Automated Tooling's real-time monitoring and data analysis features. The system provides comprehensive insights into production metrics, allowing you to identify bottlenecks, optimize workflows, and make data-driven decisions. By harnessing these analytics, you can fine-tune your operations and maximize efficiency, leading to improved productivity and cost savings.Flexibility and Customization

Every business has unique manufacturing requirements. Automated Tooling offers a high degree of flexibility and customization options to cater to your specific needs. From adjustable parameters to customizable workflows, this tooling system can be tailored to suit various production processes. Whether you are manufacturing complex components or simple products, Automated Tooling adapts to your requirements, ensuring optimal outcomes.Minimize Downtime with Predictive Maintenance

Unplanned downtime can be costly and disruptive to any manufacturing operation. Automated Tooling minimizes the risk of unexpected breakdowns by employing predictive maintenance techniques. By continuously monitoring the system's performance and analyzing data patterns, it can detect potential issues before they escalate into major problems. This proactive approach to maintenance ensures uninterrupted production, maximizing uptime and minimizing losses.Seamless Collaboration with Human Operators

Automated Tooling is designed to work in harmony with human operators, promoting seamless collaboration between man and machine. While the system automates repetitive and physically demanding tasks, it also allows operators to focus on more complex and creative aspects of production. This collaboration not only enhances productivity but also fosters a positive work environment where human expertise and innovation can thrive.Future-Proof Technology and Scalability

Investing in Automated Tooling means embracing future-proof technology. This cutting-edge system is built to adapt and evolve alongside technological advancements in the manufacturing industry. Its scalability allows you to expand your operations without the need for major reinvestments. By choosing Automated Tooling, you are setting the foundation for long-term growth and success.Certificates

With a strong foothold in the Machinery manufacturing industry, we proudly showcase an array of industry certificates that validate our commitment to excellence. These certificates, earned over the years, stand as a testament to our unwavering dedication to producing highly competitive products. By adhering to stringent quality standards and employing cutting-edge technology, we consistently deliver superior machinery that exceeds customer expectations. Our advantage lies in our ability to seamlessly integrate innovation with reliability, ensuring our products are at the forefront of the industry. We prioritize customer satisfaction by offering tailored solutions, exceptional after-sales service, and a responsive support team. Our competitive pricing, coupled with our unwavering commitment to delivering on time, further distinguishes us from the competition. Trust in our expertise, bolstered by our industry certificates, and experience the unparalleled advantages we bring to the Machinery manufacturing industry.